Introduction

In industrial food production, raw materials are not simply ingredients — they are operational parameters. A chocolate coating line, biscuit baking tunnel, or instant beverage blending system is calibrated around repeatable material behavior. Once a formulation has been validated, the production environment expects every future batch of that ingredient to perform identically.

Cocoa powder is particularly sensitive in this regard. Its properties influence viscosity, hydration, aeration, color development, and flavor balance simultaneously. When one shipment behaves differently from the previous one, the factory must adjust mixing energy, fat ratio, temperature profile, or dosing level. These adjustments slow production and introduce uncertainty into quality control.

For this reason, industrial buyers evaluate cocoa powder not only by specification sheets but by stability across time. Batch-to-batch consistency becomes more important than individual analytical values. The ingredient must behave the same next month as it did today.

industrial cocoa powder consistency

Why Consistency Matters in Continuous Manufacturing

Factories operate on fixed processing conditions. Equipment settings are optimized once and maintained to ensure efficiency. When a raw material changes behavior, operators compensate manually or alter process parameters, which interrupts the stability of the line.

Typical consequences of inconsistent cocoa powder include:

- viscosity drift in chocolate masses

- uneven color formation after baking

- unstable cream filling texture

- sedimentation in beverages

- dosing inaccuracies in automated systems

Even when all values remain technically “within specification,” small variations can accumulate into noticeable product differences.

The cost of inconsistency is therefore operational, not only sensory. It affects throughput, labor, waste, and planning reliability.

Sources of Variation in Cocoa Powder

Cocoa begins as an agricultural product, and natural variability exists at every stage before processing. Industrial cocoa production aims to reduce that variability through controlled transformation.

Bean Composition

Differences in fat distribution, acidity, and fiber structure influence how beans respond to roasting and pressing. If selection criteria change between batches, the resulting powder will behave differently during mixing and heating.

Thermal Treatment

Roasting profiles determine flavor precursors and moisture content. Slight temperature deviations alter grinding efficiency and alkalization reaction speed.

Pressing Conditions

Residual fat percentage affects viscosity and mouthfeel. Inconsistent pressing pressure produces powders that absorb fat or water differently in formulations.

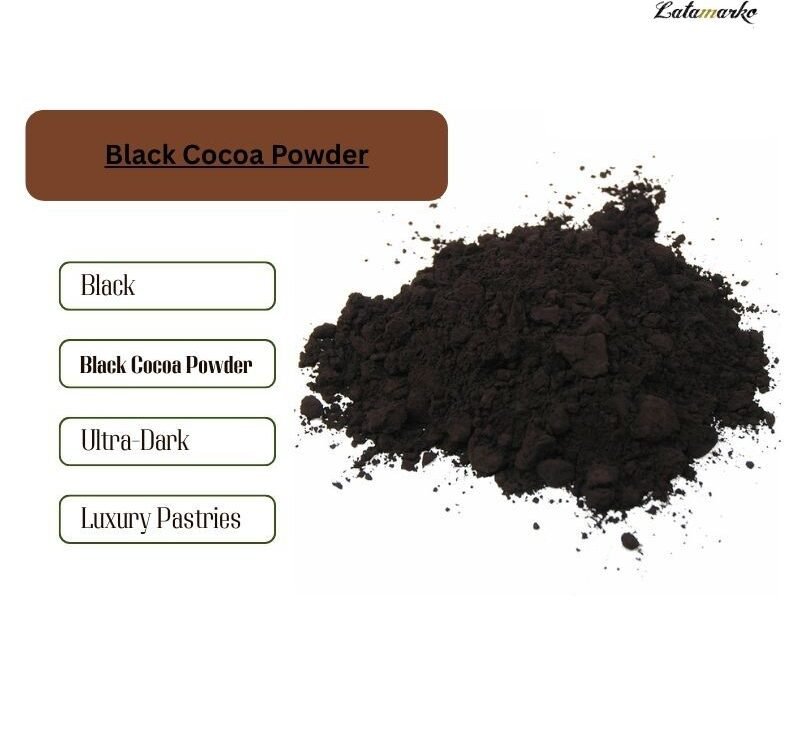

Alkalization Reaction

pH variation changes color development and dispersion behavior. Even small shifts can influence baking performance or beverage stability.

Milling and Classification

Particle size distribution determines flowability and hydration speed. Irregular grinding leads to segregation during transport and inaccurate dosing.

Each stage introduces potential variation. Consistency is achieved only when all stages are controlled simultaneously.

Controlling Variability Through Processing Discipline

Industrial cocoa processing transforms natural material into a repeatable functional ingredient. The objective is not to eliminate natural differences entirely but to regulate them within narrow operational ranges.

Standardized Raw Material Preparation

Beans are prepared to create homogeneous input before processing begins. Size classification and conditioning ensure uniform roasting and grinding behavior.

Controlled Roasting

Thermal treatment follows fixed profiles rather than operator judgment. Identical heat exposure ensures stable acidity and structural properties.

Calibrated Pressing

Presses operate under programmed pressure curves to achieve defined fat retention instead of maximum butter extraction.

Regulated Alkalization

Chemical adjustment maintains pH within a stable range so color and dispersion remain predictable.

Precision Milling

Classification loops produce repeatable particle distribution that supports stable mixing and flow.

Consistency is therefore the cumulative result of many controlled steps rather than a single final inspection.

The Role of Analytical Monitoring

Measurement confirms stability but does not create it. Laboratories verify that process control has worked correctly.

Key parameters monitored include:

- pH range

- fat percentage

- moisture content

- particle distribution

- microbiological safety

More important than individual results is their repeatability over time. Industrial customers evaluate long-term trends rather than isolated values.

Stable analytical history allows manufacturers to maintain validated recipes without repeated approval cycles.

Operational Benefits for Food Manufacturers

When cocoa powder behaves consistently, production efficiency increases in measurable ways.

Fixed Equipment Settings

Mixers, refiners, and ovens remain unchanged between deliveries. Operators do not need corrective adjustments.

Stable Product Appearance

Color and texture remain identical across production runs, protecting brand identity.

Reduced Waste

Fewer rejected batches occur because the process stays within tolerance.

Predictable Planning

Procurement teams can forecast production schedules confidently when material performance is reliable.

In high-volume manufacturing, even small improvements in stability significantly reduce operating cost.

Long-Term Supply Relationships

Industrial purchasing is based on continuity rather than isolated transactions. A supplier capable of maintaining repeatable behavior becomes integrated into the customer’s production planning.

Instead of testing each shipment independently, the customer trusts that the ingredient will perform within expected parameters. This reduces laboratory workload and accelerates release to production.

Consistency therefore builds operational confidence, which is the foundation of long-term supply partnerships.

industrial cocoa powder consistency

Practical Implementation in Structured Processing Systems

In structured processing environments such as the Latamarko cocoa manufacturing framework, production parameters are designed around stability rather than short-term yield optimization. Each stage of processing — from bean preparation through alkalization and milling — operates within defined tolerance windows to maintain repeatable functional performance.

The objective is to ensure that cocoa powder received months apart behaves identically in chocolate, bakery, or beverage systems. By aligning process control with application behavior, the ingredient becomes part of the manufacturing workflow rather than a variable input requiring correction.

Consistency as a Quality Indicator

Traditional quality perception often focuses on flavor strength or color intensity. Industrial production, however, measures quality by reliability. A material that performs identically in every batch allows continuous manufacturing without interruption.

Consistency protects three critical factors:

- operational efficiency

- product uniformity

- production planning accuracy

An ingredient meeting these conditions becomes predictable enough to support automated high-volume processing.

Conclusion

Batch-to-batch consistency transforms cocoa powder from a variable agricultural material into a dependable industrial component. Through controlled selection, processing discipline, and continuous monitoring, variability is reduced before the ingredient reaches the customer.

Manufacturers rely on repeatable material behavior to maintain fixed formulations and stable production conditions. When cocoa powder performs the same across deliveries, it supports uninterrupted operation and consistent product identity.

In modern food manufacturing, consistency is not an additional advantage — it is the primary requirement for reliable production performance.

Prepared by Dr. Meryem Bilgin

Managing Director — Latamarko