Introduction

In industrial food manufacturing, cocoa powder functions not only as a flavoring component but as a physical material moving through automated systems. It passes through storage silos, dosing units, pneumatic conveying lines, mixers, refiners, and continuous processing equipment. For this reason, the performance of cocoa powder depends strongly on its particle size distribution and resulting flow behavior.

While color and taste define consumer perception, particle structure defines manufacturing stability. Poorly controlled particle distribution leads to inaccurate dosing, inconsistent mixing, sedimentation in beverages, unstable chocolate viscosity, and processing interruptions.

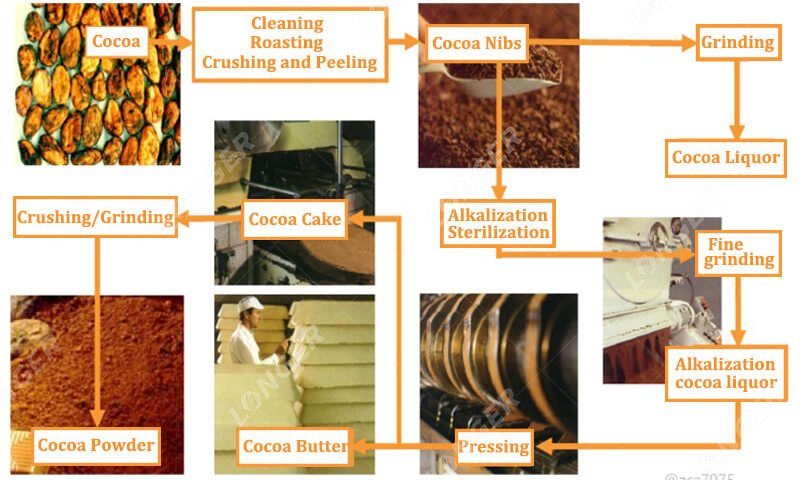

Industrial cocoa processing therefore treats milling and classification as precision engineering stages rather than simple grinding operations.

cocoa powder particle size distribution

Particle Size Distribution: Beyond Average Micron Size

Cocoa powder cannot be defined by a single particle size value.

Two powders with the same average micron size may behave completely differently in production.

Instead, performance depends on distribution across three fractions:

-

Fine particles — contribute to color intensity and smooth mouthfeel

-

Medium particles — support suspension stability and structural balance

-

Coarse particles — determine flowability and aeration characteristics

A narrow and controlled distribution ensures predictable behavior.

An irregular distribution creates separation during transport and unstable mixing.

In industrial handling, stability of distribution matters more than achieving extreme fineness.

Influence on Chocolate Processing

In chocolate systems, cocoa powder forms part of the solid particle network within the fat phase. Particle size directly affects rheology.

Fine Excess

Too many fines increase surface area, absorbing fat and thickening the chocolate mass. This requires additional cocoa butter or longer conching time.

Coarse Excess

Too many coarse particles reduce smoothness and create unstable coating behavior.

Balanced Distribution

A controlled distribution allows predictable viscosity, enabling fixed refining parameters and stable tempering performance.

Chocolate manufacturers therefore require powder whose particle behavior remains identical across deliveries.

Behavior in Bakery and Wafer Production

During dough mixing and baking, cocoa powder interacts with flour, sugar, and water. Particle size determines hydration speed and dispersion.

-

fine particles hydrate rapidly and influence color formation

-

coarse particles affect gas retention and crumb structure

If distribution varies between batches, biscuits may spread differently and wafer sheets may show uneven coloration.

Controlled milling ensures repeatable baking performance without oven or formulation adjustments.

Performance in Beverage and Dairy Systems

In liquid products, particle size distribution governs suspension stability.

Excess coarse particles settle quickly, forming sediment.

Excess fines may float and create foam layers.

A balanced distribution produces gradual hydration and uniform color dispersion, preventing separation during storage. This is essential for ready-to-drink beverages and instant powders.

Flow Behavior in Industrial Handling

Beyond formulation performance, cocoa powder must move reliably through equipment.

Factories rely on gravity feeding and mechanical dosing systems.

Poor flowability leads to bridging in hoppers, irregular feed rates, and manual intervention.

Key parameters influenced by particle structure include:

-

bulk density

-

angle of repose

-

aeration tendency

-

dust formation

Controlled milling and classification stabilize these characteristics, enabling continuous operation.

Milling and Classification Control

Industrial grinding uses staged reduction rather than single-pass pulverization. After initial milling, classification separates particles and returns oversized fractions for regrinding.

This loop continues until the target distribution is achieved.

Such controlled milling produces uniform behavior in mixing and transport. It also minimizes segregation during packaging and shipping.

In structured processing environments, particle distribution is monitored as a functional parameter rather than a purely analytical value. Within production systems such as those applied in the Latamarko cocoa processing structure, milling profiles are aligned with downstream application performance so that powder handling remains stable across different manufacturing conditions.

Relationship Between Particle Size and Moisture Interaction

Particle structure affects how cocoa interacts with water and fat phases. Uniform particles hydrate gradually and disperse evenly. Irregular fragments absorb liquid unpredictably, causing lump formation or uneven mixing.

Stable hydration behavior reduces mixing time and improves batch reproducibility, especially in high-volume automated plants.

Industrial Impact of Consistent Flow

Stable flow behavior supports:

-

accurate dosing in automated batching

-

uniform blending with sugar and milk powders

-

reliable conveying without blockages

-

reduced product loss and cleaning frequency

Manufacturers can maintain fixed processing parameters when material handling remains predictable.

cocoa powder particle size distribution

Conclusion

Particle size distribution defines how cocoa powder behaves as a physical material within industrial production systems. Controlled milling and classification create stable flowability, consistent dispersion, and predictable interaction with other ingredients.

Rather than being a secondary property, particle structure determines whether cocoa functions as a variable raw material or a reliable processing component. When distribution remains consistent across batches, manufacturers achieve uninterrupted operation and uniform product quality.

Dr. Meryem Bilgin.