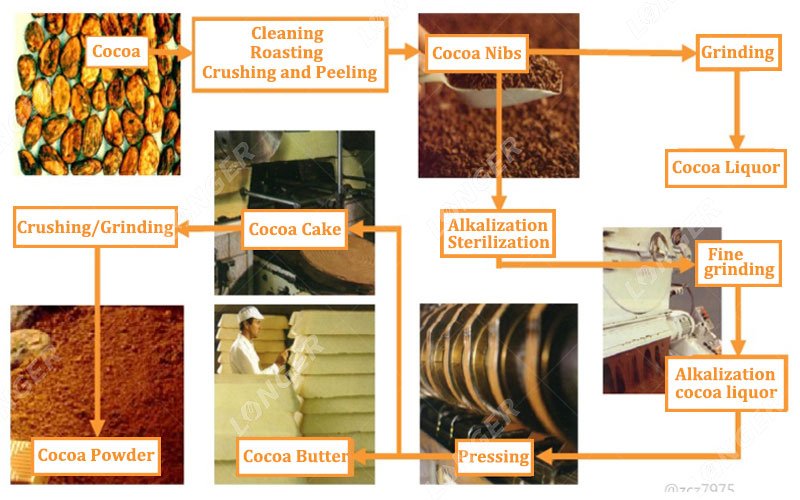

In cocoa processing, pressing is the stage where cocoa transitions from a fluid intermediate material into the structural basis of cocoa powder. After roasting and grinding create cocoa liquor, mechanical pressure separates cocoa butter from cocoa solids, producing cocoa cake — the material later milled into powder.

Although often described as a simple extraction step, pressing actually determines how cocoa powder will behave in industrial applications. Fat level directly influences viscosity in chocolate, absorption in bakery dough, dispersion in beverages, and mouthfeel in fillings. For manufacturers operating continuous production lines, the stability of this parameter is more critical than flavor intensity.

Cocoa powder performance is therefore defined not only by the presence of cocoa butter, but by the controlled amount that remains after pressing.

cocoa powder fat content control

From Cocoa Liquor to Cocoa Cake

Cocoa liquor contains approximately 50–55% cocoa butter.

Pressing reduces this fat content to a predetermined range, typically between 10% and 22% depending on the intended application.

The remaining solid portion — cocoa cake — forms the base of cocoa powder.

The mechanical separation must be controlled carefully. Excess removal leads to dry, weak functionality, while insufficient removal produces unstable flow behavior. Industrial processing does not aim for maximum butter extraction; it aims for repeatable fat retention.

Why Fat Content Matters in Industrial Formulations

Chocolate Systems

In chocolate production, cocoa powder contributes solid particles to the fat matrix. The residual fat inside the powder affects rheology.

Higher fat powder:

- smoother flow

- reduced viscosity

- softer mouthfeel

Lower fat powder:

- thicker mass

- higher structure

- stronger cocoa impact

Small variations cause measurable changes in refining and conching performance. When fat levels shift, manufacturers must alter fat dosing or processing time.

Bakery Applications

In biscuit and cake dough, cocoa fat influences water absorption and aeration.

If fat content fluctuates:

- dough consistency changes

- spread behavior varies

- texture becomes inconsistent

Stable pressing ensures predictable baking behavior without reformulation.

Beverage and Dairy Systems

In liquid applications, fat level impacts suspension stability.

Excess fat may cause surface separation, while insufficient fat produces thin mouthfeel.

Consistent residual fat allows stable dispersion during mixing and homogenization.

Pressing Mechanics and Pressure Curves

Industrial cocoa presses operate in stages rather than a single compression step.

The pressure profile determines how butter exits the cocoa structure.

Controlled pressing typically follows:

- gradual pressure increase — prepares particle structure

- high pressure phase — separates butter

- stabilization phase — equalizes cake density

If pressure rises too quickly, channels form inside the cake and extraction becomes uneven.

If pressure is insufficient, fat remains inconsistent across the batch.

Modern processing plants monitor pressure, temperature, and time simultaneously to maintain uniform fat distribution.

Structural Impact on Downstream Processing

Pressing affects not only fat percentage but also how the cocoa fractures during milling.

A well-pressed cake breaks into predictable particles during grinding.

An uneven cake produces irregular fragments that create poor flowability and unstable particle size distribution.

Because of this, pressing is indirectly responsible for:

- powder density

- dispersion behavior

- mixing performance

- color uniformity

The grinding stage cannot correct instability created during pressing.

Fat Control and Alkalization Interaction

Residual fat also influences the chemical reaction during alkalization.

Cocoa cake with uneven fat distribution absorbs alkali differently across particles.

Consequences include:

- uneven pH

- shade variation after baking

- inconsistent flavor balance

Uniform pressing ensures the chemical treatment later reacts consistently across the entire batch.

Monitoring and Process Stability

Industrial cocoa processors maintain fat content within narrow tolerances using analytical measurement after pressing. The objective is not a specific number but a repeatable range over time.

Factories that depend on continuous production evaluate consistency across shipments more than single-batch specification values.

In structured processing environments, pressing becomes a calibration stage — setting the functional identity of the cocoa powder before milling begins.

Subtle Integration into Manufacturing Practice

Within disciplined processing operations such as those applied in structured cocoa manufacturing facilities, pressing parameters are designed around application requirements rather than extraction efficiency alone. The retained cocoa butter level is matched to the behavior expected in chocolate, bakery, or beverage systems.

When the same pressure curve is maintained across production cycles, downstream manufacturers can operate fixed formulations without recalibration. The cocoa ingredient effectively behaves as a standardized component rather than a variable raw material.

cocoa powder fat content control

Logistics and Repeatability

Stable fat content simplifies not only production but also procurement planning.

Customers receiving identical functional performance across deliveries avoid repeated laboratory validation and equipment adjustments.

This stability allows long-term formulation approval — a key requirement in industrial supply relationships.

Conclusion

Cocoa pressing is the decisive stage that defines cocoa powder functionality. By controlling residual fat content, processors determine viscosity behavior, dispersion stability, and structural performance across applications.

Reliable pressing transforms cocoa from a variable agricultural material into a predictable manufacturing ingredient. The consistency achieved at this stage carries through alkalization, milling, and final application.

In modern industrial food production, fat control during pressing is not a quality preference — it is a process requirement that ensures continuous and stable manufacturing performance.