Cocoa powder used in modern food manufacturing is not simply ground cocoa beans.

It is the result of a controlled transformation process designed to convert a naturally variable agricultural material into a standardized industrial ingredient.

Chocolate coatings, biscuits, wafer creams, dairy drinks, and instant beverages all depend on predictable cocoa behavior. Manufacturers operate calibrated production lines where temperature, mixing energy, fat ratios, and flow properties are precisely adjusted. When cocoa characteristics fluctuate, the entire process must be corrected — increasing downtime, waste, and operational cost.

Industrial cocoa processing exists to prevent that variability.

The objective is not only to produce flavor, but to deliver repeatable functionality.

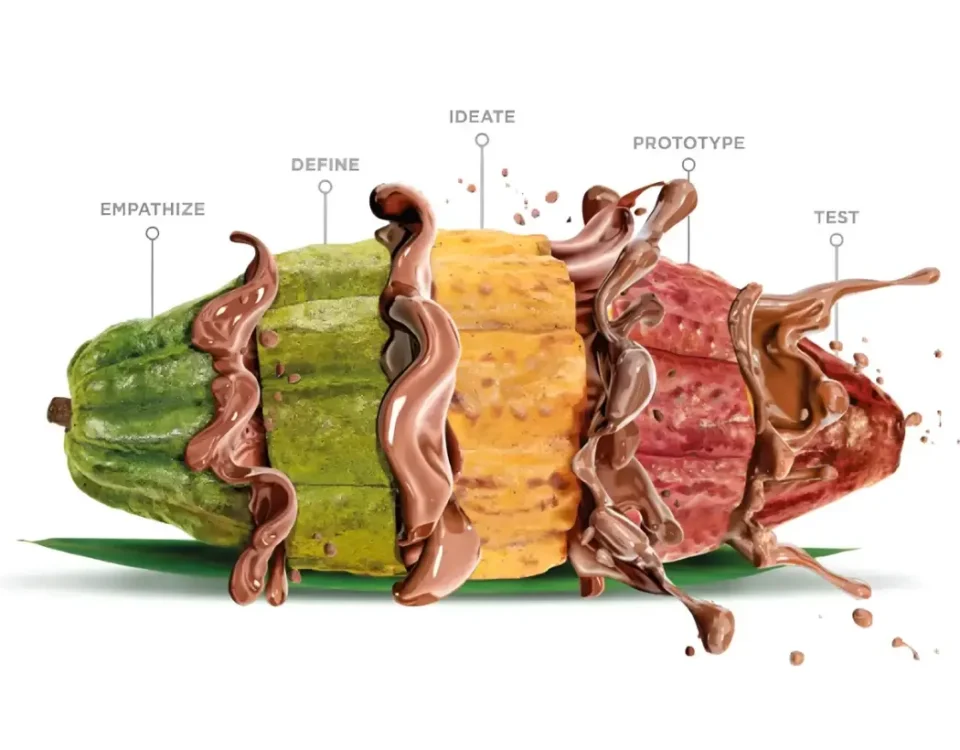

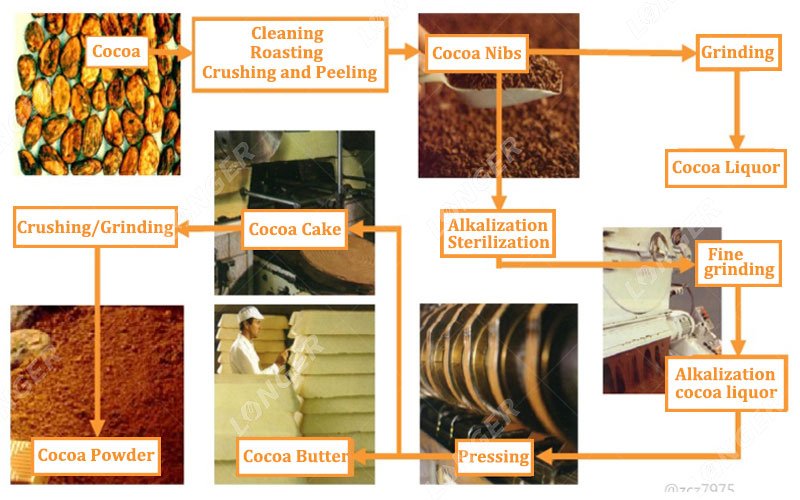

The journey from cocoa bean to cocoa powder therefore follows a structured sequence of preparation, thermal treatment, mechanical separation, chemical adjustment, and controlled milling. Each stage regulates a specific physical or chemical parameter so that the final powder behaves identically across batches and shipments.

Raw Material Selection and Preparation

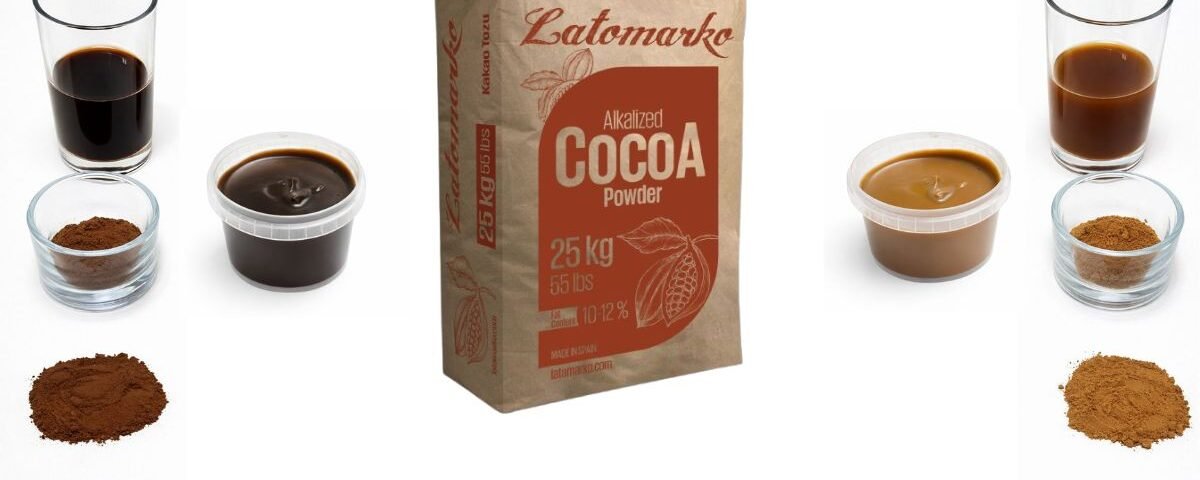

industrial cocoa powder manufacturing process

Functional Selection Instead of Origin Selection

In industrial processing, cocoa beans are evaluated primarily by how they respond to processing conditions rather than geographic origin alone. Different beans contain varying fat distribution, acidity levels, and cellular density. These characteristics influence roasting tolerance, pressing efficiency, and alkalization response.

Selecting beans based on processing behavior allows the manufacturer to stabilize production before thermal treatment even begins. A consistent raw material input reduces the range of adjustments required in later stages.

Cleaning and Conditioning

Before roasting, beans undergo preparation procedures to create a homogeneous starting material. Foreign matter removal, size sorting, and moisture conditioning ensure uniform heat penetration during roasting.

Without preparation, some beans may over-roast while others remain under-processed, leading to uneven flavor development and inconsistent powder color. Proper conditioning establishes the baseline for controlled processing.

Roasting: Thermal Stabilization of Cocoa Structure

Roasting converts raw cocoa beans into a functional processing material.

This stage influences acidity, color precursors, grinding behavior, and flavor balance.

Industrial roasting is not designed for maximum intensity but for repeatable transformation. Each batch must experience identical thermal history to maintain downstream consistency.

Objectives of Controlled Roasting

- reduce excess moisture

- soften cellular structure for grinding

- regulate acidity levels

- prepare stable color development

If roasting varies, the cocoa liquor formed later will differ in viscosity and pressing behavior. Even slight temperature deviations can affect fat separation efficiency and final powder performance.

Consistent roasting therefore creates a stable foundation for the mechanical stages that follow.

Cracking and Cocoa Liquor Formation

After roasting, beans are cracked and shells removed, leaving cocoa nibs.

These nibs are ground into cocoa liquor — a fluid suspension of cocoa solids and cocoa butter.

Liquor homogeneity is critical. The particle structure must remain uniform so the pressing stage can separate fat consistently. Variations in particle size or temperature alter mechanical resistance and cause unstable fat extraction.

In industrial processing, liquor formation transforms discrete particles into a standardized intermediate material ready for controlled separation.

industrial cocoa powder manufacturing process

Cocoa Pressing: Separation and Fat Control

Pressing divides cocoa liquor into cocoa butter and cocoa cake.

The remaining cake determines the fat content and structural behavior of cocoa powder.

Controlled Pressure Stages

Industrial presses operate using programmed pressure curves rather than fixed force. The goal is predictable fat retention rather than maximum extraction.

Controlled pressing produces:

- defined residual fat percentage

- stable density of cocoa cake

- repeatable powder viscosity

- uniform interaction with sugar and fats in formulations

If fat content fluctuates, chocolate flow changes, biscuit texture shifts, and beverage suspension stability decreases.

Pressing therefore establishes the functional performance of the final powder before chemical treatment even begins.

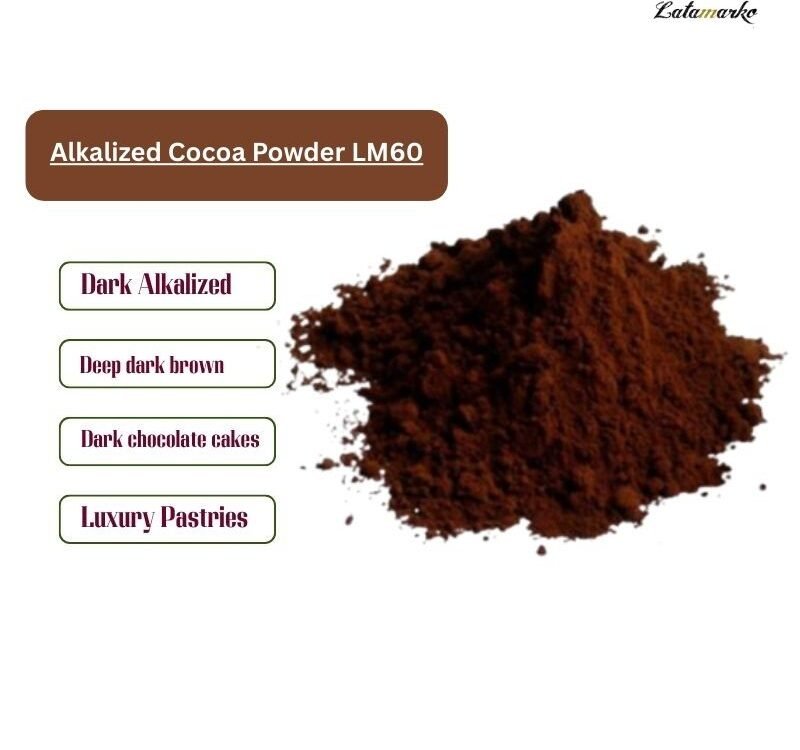

Alkalization (Dutch Process): Chemical Adjustment

Natural cocoa contains organic acids that affect dispersion, taste, and viscosity.

Alkalization modifies the pH to stabilize behavior in food systems.

Process Conditions

The cocoa cake is treated with alkalizing agents under regulated temperature and moisture conditions. The reaction must remain within a narrow range to prevent over-correction.

A controlled alkalization process provides:

- balanced flavor profile

- darker and stable color

- improved wettability

- predictable rheology in chocolate systems

Color consistency during baking and heating depends strongly on pH stability. Industrial users require powders that develop identical shades in repeated production cycles.

Grinding and Milling

After alkalization, cocoa cake is milled into powder.

This stage determines dispersion behavior and flow performance.

Particle Size Distribution

Industrial cocoa powder requires a balanced distribution:

- fine particles → smooth texture and color intensity

- medium particles → suspension stability

- coarse particles → flow and aeration behavior

Irregular grinding causes clumping, sedimentation, or inaccurate dosing.

Uniform milling ensures predictable handling across automated equipment.

Powder Handling and Standardization

Following grinding, cocoa powder undergoes classification and stabilization before packaging. Bulk density, moisture, and flowability are adjusted to maintain consistent handling properties.

In large factories, cocoa passes through hoppers, conveyors, and mixing systems. Stable flow characteristics prevent bridging and allow continuous operation.

At this stage, cocoa becomes a standardized processing ingredient rather than a variable agricultural material.

Quality Control and Verification

Industrial cocoa powder must meet defined analytical parameters.

Testing confirms that functional behavior remains within tolerance.

Typical verification includes:

- pH range

- fat percentage

- moisture content

- particle size distribution

- microbiological safety

These measurements are not marketing specifications but operational guidelines. Manufacturers depend on them to maintain fixed formulations.

Consistency ensures that once a product is approved, future production runs require no reformulation.

Packaging and Logistics Integration

Packaging is part of industrial processing, not a separate step.

Uniform bag structure, palletization, and lot identification allow direct integration into production warehouses.

Predictable shipment scheduling supports factory planning.

Reliable supply prevents interruptions in continuous manufacturing environments.

Cocoa powder therefore reaches the customer as a ready-to-use processing input rather than a material requiring adjustment.

From Agricultural Material to Industrial Ingredient

The full cocoa processing chain transforms natural variability into controlled functionality.

| Stage | Purpose |

|---|---|

| Preparation | stabilize raw material |

| Roasting | thermal consistency |

| Liquor Formation | structural uniformity |

| Pressing | fat control |

| Alkalization | chemical stability |

| Grinding | mechanical behavior |

| Verification | functional reliability |

Each step removes uncertainty before the ingredient reaches the production line.

Importance for Food Manufacturers

Industrial production depends on predictable ingredients.

Stable cocoa powder allows:

- fixed equipment settings

- uniform product appearance

- consistent sensory profile

- reduced waste

- continuous production flow

Instead of adapting the process to the ingredient, manufacturers can rely on the ingredient adapting to the process.

industrial cocoa powder manufacturing process

Conclusion

Industrial cocoa processing is a controlled engineering sequence rather than simple grinding. The purpose is to convert a naturally variable bean into a reproducible functional powder suitable for high-volume food manufacturing.

Through preparation, roasting, pressing, alkalization, milling, and verification, cocoa becomes a stable component in chocolate, bakery, dairy, and beverage systems.

The success of the final product depends less on origin and more on processing discipline. When each stage operates within defined limits, the resulting cocoa powder behaves identically across batches, shipments, and production cycles.

In modern food manufacturing, consistency is not a quality advantage — it is a production requirement.